The Military Turns to 3D Printing

June 08, 2023

The military is always looking for ways to stay ahead of the curve, and incorporating 3D printing into the defense sector is one way in which they are doing just that. 3D printing is being used by military units from different countries all over the world. They are creating everything from replacement parts for critical vehicles, ships, and aircraft as well as new designs for safety equipment being worn by service members to prototypes for new defense weapons, medical supplies, and even runways and bunkers.

3D printing technology is revolutionizing the way militaries around the world procure and maintain their equipment. In the future, 3D printing will become even more prevalent in the military, with the technology being used to print everything from weapons and ammunition to food and medical supplies.

One of the biggest advantages of 3D printing is that it allows for on-demand manufacturing, which means that militaries can print the items they need when they need them. This could be particularly useful in combat situations when time is of the essence and traditional supply chains are disrupted.

The use of 3D printing in the military enables them to be more self-sufficient. With 3D printers, militaries can print replacement parts and components for their equipment, rather than having to rely on outside suppliers. This could be a critical capability in wartime, when enemy forces may try to cut off supply lines.

3D Printing Spare Parts for the Military

One area where the military is using 3D printing is to create replacement parts for land vehicles, ships, and aircraft. In the past, if something needed a new part, it would have to be ordered from a manufacturer and then shipped to the military base or flown in for a vessel deployed at sea.

This could take weeks or even months, especially with the current supply chain issues plaguing the entire world and keeping important parts stuck in ports due to chip shortages and pandemic-created backlogs.

With 3D printing, the military can create the parts they need on-site whether that is on base, at the front lines, or at sea. In a matter of hours or days, they can be up and running again which can be critical in a warzone or where lives are in danger.

Thanks to 3D printing technology, vehicles, and other legacy machinery can be kept out of retirement much longer when a spare part is able to be 3D printed to put it back into service.

Instead of spending thousands of dollars to have a single custom part made, they are able to design and 3D print it in tough materials and even metal to save millions of dollars a year.

Creating Tools and Jigs

The various branches of the military have all discovered the benefit of 3D printing when it comes to creating tools and jigs to repair current equipment or install new parts.

Whether that is a 3D printed multitool they can clip to their belts or jigs that can help guide them to attach helicopter blades more safely, the possibilities are endless for the Department of Defense when it comes to 3D printed tools.

The military has always been on the cutting edge of technology, and 3D printing is no exception. The ability to quickly and easily create complex tools on the fly in a matter of hours is a huge asset in any field, but especially on the battlefield where time is often of the essence and sometimes lives are at stake.

Using 3D Printing to Improve Strength and Durability of Equipment

3D printing technology is being used by the military to create prototypes and design new equipment. This technology benefits the military because it allows for the faster creation of prototypes and quicker turnaround times for design changes. Additionally, 3D printing can be used to create customized parts and pieces that fit the specific needs of the equipment and improves workflow.

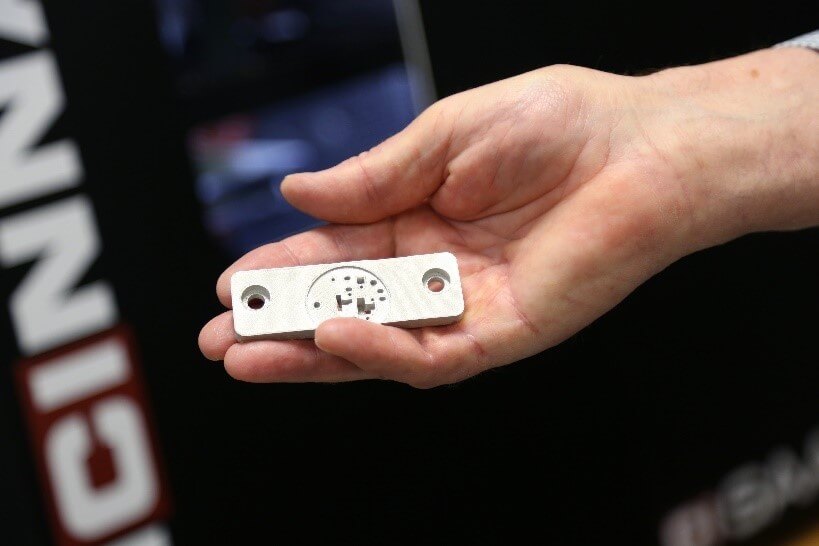

Sometimes it is as simple as designing housings for existing equipment to help protect it from damage in combat or during heavy use. For example, in the image above, a strong 3D-printed enclosure was designed to protect an antenna from being snapped off near the base during heavy use and driving through thick brush.

There are countless ways in which the Military is using 3D printing to improve the workflow of their service members as well as protect the gear they already have while also ensuring a longer life for those pieces of equipment as they are being used on a daily basis.

3D Printed Medical Devices and Supplies for the Military

Another area where the military is using 3D printing is to create medical supplies. This is especially important in combat situations, where time is of the essence. 3D-printed medical supplies can be produced quickly and easily in the field, which means soldiers can be treated faster and have a higher chance of survival in combat situations.

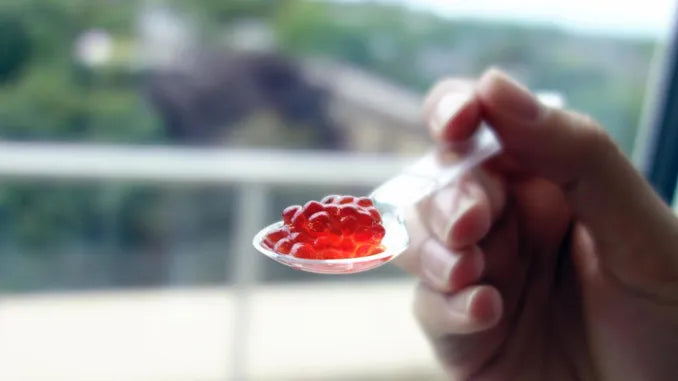

From custom-made Epi-Pen carrying cases and stethoscopes to I.V. line control, tracheal tubes, splints, casts, covid swabs, face shields, earplugs and so much more – the department of defense units around the globe are finding hundreds of ways to create medical devices with 3D printing technology.

3D Printed Military Bunkers, Bridges, and Runways

The military has partnered with companies like ICON to start building 3D-printed barracks to house service members for training missions. They have also been using 3D printing to create bunkers, vehicle hide structures, bridges and buildings in various locations around the world to serve to support and house military personnel and machinery at bases as well as in the field.

These large structures are being created using giant robotic 3D printers that extrude concrete. Once the military use has ended, the buildings, bridges and structures can then be left behind after a natural disaster or wartime mission for local communities to use once the mission is complete.

3D printed runway panels are also being created for use in areas where the runways are unstable and too dangerous for military personnel to land safely or where there is no runway at all and military aircraft need to land in order to complete their missions or bring in supplies to ground troops.

Using 3D Printing to Make Propellers, Vehicle Hulls and More

French company Naval Group has 3D printed a propeller which is composed of five 200 kg blades. The propeller was eventually fitted to the Andromeda, a mine-hunting ship. By using 3D printing technology they have drastically reduced the construction time and minimized the number of materials used to create this component and saved thousands of dollars in the process.

The Applied Science & Technology Research Organization, (also known as ASTRO America), has been been working on the Jointless Hull Project with the US Army to develop and deliver a hull for combat vehicles. Their hope is that this project will help to reduce manufacturing time and lower production costs. This will also reduce the weight of the vehicle and increase its performance and survivability for the service members who are manning them.

There are countless ways in which the military is currently working to make lighter weight and safer machinery, equipment and vehicles for use in combat as well as daily operations. 3D printing is also allowing for designs that can be repaired quickly and easily, on the spot without need to rely on outside manufacturers and supply chain issues.

Prototyping Safety Equipment with 3D Printing

For the military, 3D printing is also opening up a whole new world of possibilities in areas where they are constantly looking to improve functionality, safety, and comfort for their service members.

For example, General Lattice and the U.S. Army have paired up to improve the impact absorption of the Army's combat helmet through 3D printing by incorporating advanced lattice geometries. The hope is to improve soldier protection in the field and a higher chance of survival after suffering a head impact. The 3D printed materials will be tested in real-world situations to help improve the design and ultimately begin implementing its use in the field.

Whether they are reworking designs for face shields, masks, and other pieces of safety gear, now more than ever, the ability to 3D print a prototype and make adjustments in a matter of minutes is crucial.

The Future of 3D Printing in the Military

In the future, 3D printing technology will become even more sophisticated and widespread, and it will have a transformative impact on the way militaries operate.

3D printing technology is revolutionizing the military industry by providing a way to quickly and cheaply produce spare parts, prototypes, and even entire weapons systems. The technology is still in its early stages, but the potential applications for 3D printing in the military are vast and could change the way wars are fought and natural disasters are responded to in the future.

For more information on 3D printers that military branches are utilizing, please visit our shop at shop3duniverse.com.