2024 3D Printing Trends to Watch For

January 04, 2024

The new year is upon us and exciting things are happening in the 3D printing and additive manufacturing world as we say hello to 2024! According to industry leaders and AI analysts, there are multiple trends expected for this year that are rather exciting and we are looking forward to seeing how this year unfolds.

Below, are some of the top predicted trends to watch out for in 2024.

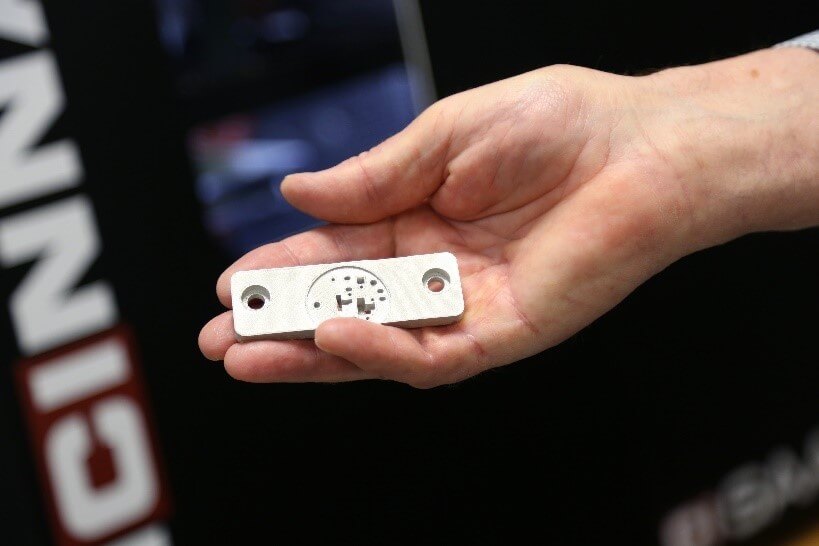

3D Printing and Metal Materials

One of the key top trends that could continue into 2024 is the increased use of metal materials in 3D printing. Metal 3D printing has been gaining traction due to its ability to produce strong, durable parts that can withstand high temperatures and pressures. This makes it ideal for industries such as aerospace, automotive, engineering, medical and the military and we expect to see even more industries working with these materials this year including the jewelery industry.

The technology is predicted to become more accessible and cost-effective, which could lead to wider adoption.

The field of metal-infused 3D printing materials is rapidly evolving, with a variety of different metals being used to create high-strength, durable parts. One of the most common metals used in 3D printing is titanium, known for its strength and light weight, making it ideal for aerospace and automotive applications. Stainless steel is another popular choice due to its corrosion resistance and durability, often used in industrial and medical applications. Aluminum, known for its light weight and thermal conductivity, is also frequently used, particularly in the automotive and electronics industries.

More recently, researchers have been exploring the use of more exotic metals like Inconel, a superalloy that can withstand extreme heat and pressure, and precious metals like gold and silver for jewelry and electronic applications. Additionally, metal composite materials, which combine metal with other materials like carbon fiber or plastic, are being developed to create parts with unique properties, such as enhanced strength or reduced weight.

We are excited to see what 2024 brings to the table!

Adoption of AI

Manufacturing industries are increasingly integrating Artificial Intelligence (AI) into 3D printing processes to enhance efficiency and productivity. AI algorithms are used to optimize the design process, enabling the creation of complex structures that would be difficult to achieve manually. These algorithms can also predict potential errors or failures in the design before printing, saving time and resources.

In addition, AI can monitor the printing process in real-time, adjusting parameters on-the-fly to ensure the highest quality output. This includes factors like temperature, speed, and layer thickness, which can significantly impact the final product's properties. Furthermore, AI can analyze post-production data to identify patterns and trends, providing valuable insights for future production runs. This use of AI in 3D printing not only increases the speed and efficiency of production but also improves the quality and reliability of the printed components, making it a valuable tool in modern manufacturing.

For example, Bambu Lab 3D printers have taken the 3D printing world by storm. Having won multiple awards, including Time Magazine's Best Inventions of 2022 and 3D Printing Industry Awards 2023 Desktop FFF 3D Printer of the Year Winner, Bambu Lab has raised the bar for the 3D printing experience. Their printers feature AI-assisted printing and can inspect the first layer and detect that dreaded spaghetti monster!

It looks like 3D printer manufacturers are going to have to step up their game in 2024!

Sustainability

Sustainability is another area where 3D printing could make a significant impact. As concerns about environmental impact continue to grow, there is increasing interest in using 3D printing to reduce waste and promote circular economy principles. This could involve the use of recycled materials in 3D printing, or the development of 3D printers that can recycle their own waste.

There is a wonderful trend happening now, with more and more eco-friendly materials being developed as well as companies who are turning towards implementing cardboard spools to replace the plastic previously being used for filaments.

Faster Print Speeds

As we look towards 2024, one of the anticipated trends in the 3D printing industry is the development and implementation of faster printing speeds. The speed of 3D printing has traditionally been a limiting factor in its adoption for mass production. However, advancements in technology are expected to significantly reduce printing times.

This includes improvements in printer hardware, such as more efficient extruders and lasers, as well as software enhancements for better slicing and toolpath generation. Faster 3D printing could revolutionize industries by enabling rapid prototyping and reducing the time from design to product. This would not only increase productivity but also allow for greater flexibility and customization in manufacturing processes.

In the above video, the Bambu Labs 3D Printers demonstrate their 600mm/s with a 10,000mm/s acceleration while printing the "Benchy."

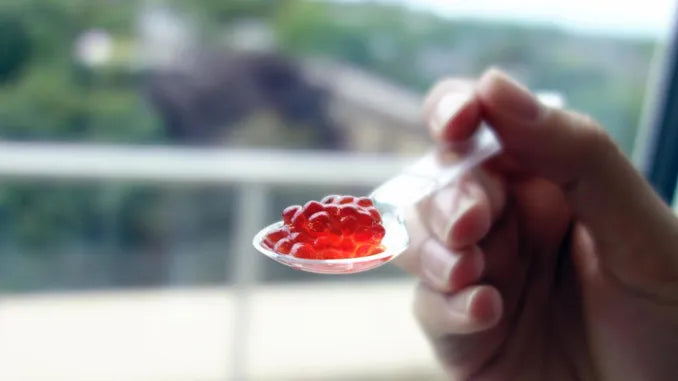

Bioprinting

The growth of 3D bioprinting is another trend in 3D printing to watch for this year. This technology involves the use of living cells to print organs and tissues, and it has the potential to revolutionize the medical field. While still in its early stages, 3D bioprinting is expected to make significant strides in the coming years, with the possibility of printing functional organs for transplantation in 2024.

Rise of Mid-range 3D Printers

The rise of mid-range 3D printer technologies is a significant trend in the additive manufacturing industry. As the technology matures, companies are focusing on developing 3D printers that strike a balance between affordability and performance. These mid-range printers are designed to be accessible to small businesses, educational institutions, and hobbyists, while still offering the advanced features and capabilities typically found in higher-end models.

One of the ways companies are achieving this is by integrating AI into their 3D printers. AI can optimize the printing process, improving speed and efficiency, and reducing the likelihood of errors. This allows for faster production times without sacrificing quality. Additionally, advancements in technology and economies of scale are driving down the cost of 3D printers, making them more affordable for a wider range of users. This democratization of 3D printing could lead to increased adoption and innovation in the field.

Learn More About 3D Printing

Please visit our website to learn more about the different types of 3D printers available in our shop. We are always happy to answer your questions and offer suggestions to help you find the right machine for your needs.

Feel free to email us at info@3duniverse.org or head to our shop to browse our collection of 3D printers.